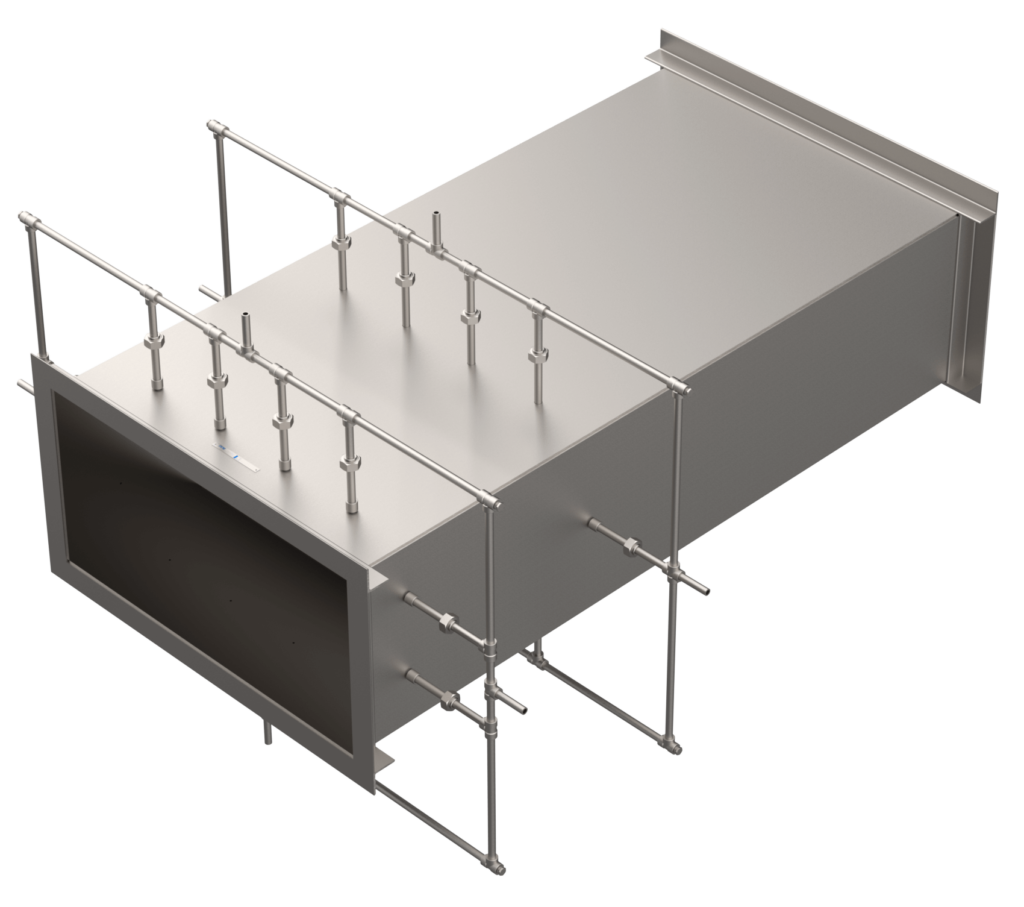

Flexible & Accurate Rectangular Venturi Flow Meters

The HVT-designed Rectangular Venturi Flow Meter from Primary Flow Signal offers substantial design and engineering flexibility, with end arrangements including flanged, mechanical joint, or weld-end connections, combined with a variety of body materials and coatings. These options allow each meter to be tailored to meet pressure, temperature, flow range, line fluid, line size, laying length, and cost objectives specific to the application.

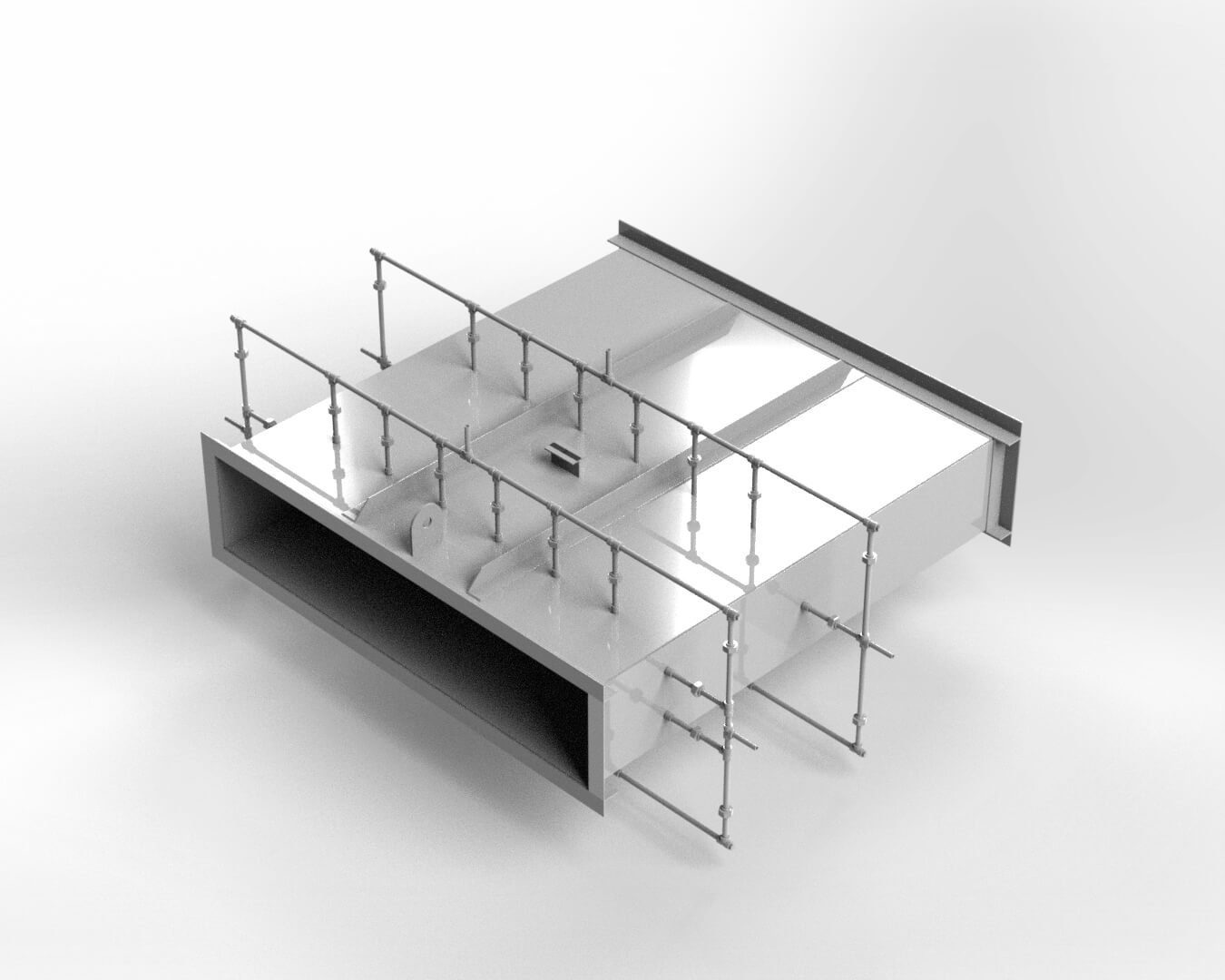

The rectangular Venturi design delivers the same proven accuracy and low head loss as a circular Venturi, but without requiring a transition from rectangular duct to round pipe for high-accuracy flow measurement. With no specific size limitations, the rectangular profile can be fully fabricated or cast in place with fabricated inlet and throat sections. A wide selection of secondary instrumentation is available, including direct interface taps, annular pipe chambers, multi-taps, and sealed diaphragm sensors. Designs corresponding to ASME MFC and ISO 5167 standards are also available. Its key advantages include:

- Extended Service Life: No moving parts and reduced susceptibility to erosion ensure long-term, low-maintenance performance.

- Stable Accuracy in Challenging Conditions: Proven Venturi design achieves high accuracy and repeatability, even at high velocities.

- Flexible Sizing & Construction: No practical size limitations, with fabrication or cast-in-place options to match unique installation requirements.

- Minimal Installation Effects: Operates with no downstream effect and minimal upstream straight-run requirements.

- Wide Turndown Ratios: Depending on the model and secondary instrumentation, ratios of 10:1, 20:1, 50:1 and greater can be achieved.

- Versatile Installation: Designed to mount in any position to fit system constraints.

Typical applications include large-scale HVAC and air handling systems, industrial flue gas and exhaust streams, municipal and industrial ductwork where rectangular transitions would otherwise be required, and high-velocity flow measurement in both clean and contaminated gas or air systems.

Rectangular and square venturi meters offer an ideal solution for applications involving environmental compliance such as carbon capture projects as well as significant cost savings, particularly in large conduit sizes where a conversion to a circular design, for measurement purposes, would be expensive.

Rectangular Venturi Specifications

Uncalibrated: +/- 0.75%

Rectangular Venturi Model Types

Model Types

- RFVF – Fabricated Venturi Flanged

- RFVW – Fabricated Venturi Butt Weld Ends

Rectangular Venturi Materials

Common Materials

- Carbon Steel 304 / 316SS

Other Materials

- Aluminum

- Chrome Moly

- Duplex S/S

- Hastelloy B & C

- Monel

- 321 SS

- Tantalum

- Titanium

- Zirconium

Rectangular Venturi Meter Certifications

PFS is a contributor to various international standards committees, fully supporting our staff’s memberships to these commissions.

Individual products follow relevant industry regulations, including requirements specific to the oil and gas, water/wastewater, and power generation industries.

PFS maintains the following certifications, standards & compliances:

- ISO 9001

- AGA

- ASME S & U

- API

- ANSI

- European Pressure Equipment Directive (PED)

Applications

HVAC & Air Handling

Rectangular Venturi meters are widely used in large-scale HVAC and air handling systems, where they provide accurate, repeatable measurement of duct air flows. Their rectangular design eliminates the need for transitions to circular piping, reducing cost and simplifying installation in new and retrofit projects.

Industrial Flue Gas & Exhaust

In industrial facilities, Rectangular Venturi meters deliver dependable measurement of flue gases and exhaust streams. Their rugged construction withstands high velocities and variable flow conditions, making them ideal for continuous-duty environments

Refineries & Steel Mills

For heavy industrial applications, including refineries and steel mills, these meters offer long-term accuracy in combustion air, process gas, and other harsh gas-flow environments. Their proven Venturi design ensures reliability despite high temperatures, abrasive particles, or contaminated gas streams.

Heater & Combustion Air Applications

Rectangular Venturi meters are commonly applied in heater systems, furnaces, and combustion air lines, where they deliver stable performance and efficiency at high velocities. Their flexibility in size and installation orientation makes them suitable for both clean and contaminated air and gas flows.

Rectangular Venturi Flow Meter Expertise Since 1983

Proven Accuracy in Air & Gas Measurement

For more than four decades, PFS has been a trusted leader in Venturi technology, delivering precision flow measurement solutions across municipal and industrial applications. The Rectangular Venturi Meter provides the same dependable accuracy and low head loss as a circular Venturi, while eliminating the need for costly transitions from rectangular ductwork to round piping. With no moving parts and a robust, fully fabricated or cast-in-place design, these meters deliver long-term reliability in both clean and contaminated air or gas streams.

Tailored Engineering & Application Support

Every duct system has unique performance requirements, and PFS engineers provide complete support to ensure optimized results. From hydraulic analysis, CFD modeling, and calibration to start-up assistance and instrumentation integration, each Rectangular Venturi is engineered to meet specific size, flow range, and installation conditions. Rehabilitation and recertification services further extend meter life, lowering total cost of ownership compared to short-life differential pressure devices.

Certified Quality & Compliance

Rectangular Venturi Flow Meters are manufactured under the industry’s most rigorous quality programs. PFS maintains ASME S & U, ISO 9001, and PED certifications, with designs also available to meet ASME MFC and ISO 5167 standards. For critical industrial, refining, or utility applications, meters can also be supplied with Canadian Registration Numbers (CRN) when required—ensuring quality, traceability, and regulatory compliance.