Industry-Leading Flow Conditioners

Flow conditioners are essential flow-straightening devices designed to remove swirl, turbulence, and velocity profile distortions caused by elbows, valves, diameter changes, and other upstream pipeline disturbances. Installed ahead of a flow meter, they help ensure a fully developed, symmetrical flow profile, significantly improving measurement repeatability and reducing uncertainty. Two primary styles are available to match application needs:

Flow Straightening Designs:

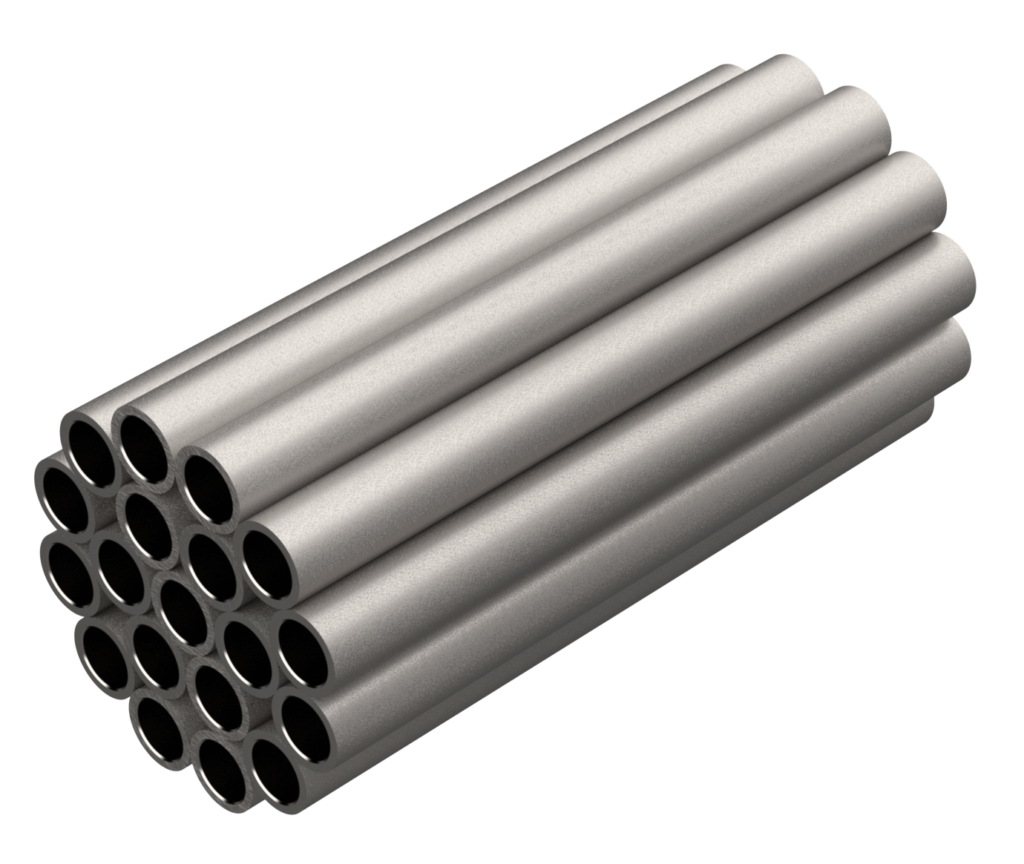

Tube Bundle Flow Conditioners

Effective for reducing swirl generated by upstream piping elements. Best suited for installations where swirl control is the primary requirement.

Flow Isolating Designs:

Plate-Type Flow Conditioners

Optimize both swirl removal and velocity redistribution while introducing lower permanent pressure loss compared to tube bundles. Plate-type units restore flow symmetry across a range of Reynolds numbers and support liquid and gas applications.

These devices offer a cost-effective way to mitigate installation effects, protect meter accuracy, and reduce the amount of upstream straight-run piping required. When properly selected and installed, flow conditioners can eliminate up to 80–90% of pipeline swirl and enhance meter performance in virtually any flow measurement system.

Flow Conditioner Key Advantages:

- Design Flexibility: Available in both tube bundle and plate-type configurations to match process requirements

- Measurement Stability: Restores flow symmetry and minimizes profile distortions for optimal meter accuracy

- Reduced Straight-Run Requirements: Enables shorter meter runs while maintaining high repeatability

- Lower Pressure Loss Options: Plate-type conditioners typically introduce less pressure loss than tube bundles

- Broad Applicability: Effective for liquids, gases, and applications with suspended solids

- Disturbance Isolation: Shields meters from upstream turbulence, noise, and pulsation effects

Flow conditioners function by reshaping and stabilizing the velocity profile before the point of measurement. By reducing swirl and reestablishing uniform flow, they help flow meters achieve higher accuracy, consistent reproducibility, and lower overall measurement uncertainty, even in constrained or disturbed piping environments.

Typical applications include natural gas and methane service, water and light hydrocarbons, chemical and petrochemical processes, pulp and paper facilities, mining and refining operations, and any system requiring accurate volumetric or mass flow measurement.

Flow Conditioner Specifications

Flow Conditioner Model Types

Model Types

- CPF – Conditioner, Plate, Flanged

- CPW – Conditioner, Plate, Weld-in

- CTBF – Conditioner, Tube, Bundle, Flanged

Flow Conditioner Materials

Typical material selections for standard applications:

- Stainless Steel (304 / 316SS)

- Carbon Steel

Other options for material selection:

- Aluminum

- Monel

- Duplex S/S

- 321 SS

- Hastelloy B & C

- Alloy 600

PFS Flow Conditioner Certifications

PFS is a contributor to various international standards committees, fully supporting our staff’s memberships to these commissions.

Individual products follow relevant industry regulations, including requirements specific to the oil and gas, water/wastewater, and power generation industries.

PFS maintains the following certifications, standards & compliances:

- ISO 9001, ISO 5167

- AGA 3

- ASME S & U

- ASME PTC6

- API 14.3

- PTC 19.5

- ANSI

- European Pressure Equipment Directive (PED)

Applications

Water & Wastewater Treatment

Municipal and industrial water systems use flow conditioners to improve meter accuracy in pump stations, treatment trains, and distribution networks. They help normalize flow in applications with limited straight-run lengths, variable velocities, or non-ideal hydraulic conditions.

Industrial Processes

Industries with large-diameter piping, high-energy pumps, and frequent directional changes rely on flow conditioners to stabilize flow for abrasive-slurry lines, chemical dosing, stock preparation, and bulk liquid handling.

Power Generation & Utility Systems

Flow conditioners support accurate measurement in cooling water systems, boiler feedwater, auxiliary gas lines, and chemical feed loops. Their ability to reduce swirl and turbulence improves reliability in both conventional and renewable power plants.

Oil & Gas

Complex piping layouts in refineries and chemical plants create turbulent, asymmetrical flow conditions. Flow conditioners restore a stable velocity profile ahead of meters used for process control, product transfer, blending operations, and high-value liquid measurement.

Industry-Leading Flow Conditioner Manufacturer Since 1983

Four Decades of Proven Expertise

For over 40 years, Primary Flow Signal has engineered flow-conditioning solutions that enhance accuracy and reliability in demanding measurement environments. Our flow conditioners are trusted across municipal, industrial, energy, and process applications for their consistent performance and long-term durability

Custom Solutions & Support

Every piping system introduces unique swirl, turbulence, and installation effects. That’s why PFS designs flow conditioners to meet precise application requirements, whether integrating with Venturi meters, orifice plates, flow nozzles, or other primary elements. Our team provides engineering guidance, sizing support, and technical consultation to ensure optimal flow profile correction and measurement accuracy.

Certifications & Approvals

PFS flow conditioners are manufactured under ISO 9001 quality standards and can be supplied with ASME, PED, and Canadian Registration Number (CRN) documentation when required. This ensures full compliance for critical infrastructure and global project specifications.