Industry-Leading Orifice Plates

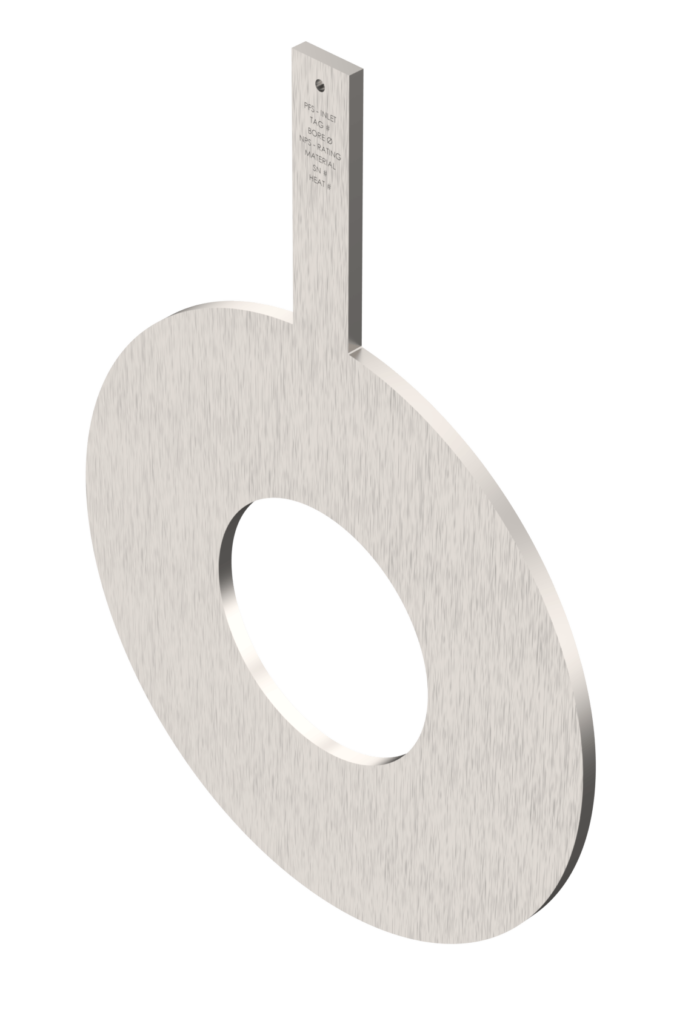

Orifice plates are one of the most common differential pressure type flow elements for the measurement of clean liquids, gases and steam flow.

Orifice plates are used for measuring and controlling fluid flow and can also be used to reduce pressure in a pipe system. The square-edged, concentric paddle-type orifice plate with flange taps is the most commonly used differential pressure (DP) flow element in U.S. industrial applications. Its popularity stems from its:

- Design Simplicity & Compatibility: Easy to install and ideal for retrofits or installations in diverse piping configurations

- Cost Efficiency: Minimizes capital investment without compromising reliability

- Serviceability: Plates are easily replaced when process conditions or flow rates change, or when accuracy degrades over time

- Proven Accuracy: Delivers dependable measurement accuracy when installed according to industry standards (e.g., ISO 5167, ASME MFC)

- Rapid Availability: Standardized construction allows for fast manufacturing and short lead times for most sizes

Based on the Bernoulli principle, this flow element determines flow rate by measuring the differential pressure across the orifice bore. The constriction created by the orifice causes a measurable pressure drop, which correlates directly to volumetric or mass flow rate when using proper calibration and flow coefficients.

Compared to other DP elements, such as Venturi meter or flow nozzles, orifice plates offer a lower-cost solution with minimal installation requirements, though they may introduce slightly higher permanent pressure losses.

Typical applications include potable water, high-pressure steam, combustion air, compressor surge control, oxygen & nitrogen measurement for air separation plants, petrochemical and chemical plants process measurement and control (alcohol, ethylene, chlorine, etc.).

Orifice Plate Specifications

*as limited only by the materials of construction and capabilities of the associated secondary device(s) used

Uncalibrated: +/- 0.50% to 0.75%, beta dependent

*accuracy is directly contingent upon the presence of the sharp edge in the orifice bore

Orifice Plate Types

Model Types

- OP — Orifice, Plate – “E2” = OP0 Universal, OP2 Paddle, OP6 RingJoint, OP9 Integral

- OPTR — Orifice, Plate, Threaded, Run ( NO Flange Union ) Welded In-Line

- OPWR — Orifice, Plate, Welded, Run ( NO Flange Union ) Welded In-Line

- OUP — Orifice, Union, with Plate

- OUPFR — Orifice, Union, Plate, Flanged, Run

- OUPWR — Orifice, Union, Plate, Welded, Run

Orifice Plate Materials

Typical material selections for standard applications:

- 304 stainless steel

- 316 stainless steel

Other options for material selection:

- Monel

- Hastelloy

- Titanium

- Brass

All equipment is available, cleaned for oxygen service if required.

All plates are stamped with identification data including material grade, bore size, line size, flange rating and tag number.

Orifice Plate Certifications

PFS is a contributor to various international standards committees, fully supporting our staff’s memberships to these commissions.

Individual products follow relevant industry regulations, including requirements specific to the oil and gas, water/wastewater, and power generation industries.

PFS maintains the following certifications, standards & compliances:

- ISO 9001

- AGA

- ASME S & U

- API

- ANSI

- European Pressure Equipment Directive (PED)

Note:

- All products can also be supplied with Canadian Registration Number (CRN)

- All materials are mill-certified and of first quality

- Each orifice plate is manufactured with strict adherence to ISO 9001 certification standards, thereby applying numerous inspections at key points in the production process, assuring the squareness and sharpness of the bore edge remain well within the tolerances permitted by the above-referenced codes and standards.

Applications

Wastewater & Water Treatment

Orifice plates are widely used to measure natural gas flow, monitor crude oil and refined product pipelines, and manage flow in offshore and onshore well systems. They are also commonly used in gas processing and compression applications.

Oil & Gas

Orifice plates are widely used to measure natural gas flow, monitor crude oil and refined product pipelines, and manage flow in offshore and onshore well systems. They are also commonly used in gas processing and compression applications.

Power Generation

Orifice plates are used to monitor raw and treated water flow, measure chlorine gas dosing, control sludge and chemical feed rates, and manage effluent discharge.

Industrial

Orifice plates are widely used across a range of industrial sectors, including building systems, mining, chemical processing, and more. Common uses include measuring flow in HVAC systems, chemical dosing, drying system control, and other industrial applications requiring the monitoring of steam, gas, and fluid flow.

Industry-Leading Orifice Plate Supplier Since 1983

Four Decades of Proven Expertise

PFS has over 40 years of experience with industry-leading accuracy and reliability, including over one million of its patented HVT Venturi meters in service worldwide. We offer complete in-house design, machining, fabrication, welding, NDT / NDE, calibration, and finishing, along with continued service and rehabilitation of flow meter installations.

Custom Engineered Services & Unmatched Support

PFS offers a full range of flow measurement services backed by a team of experienced dP flow experts. From flow calculations and start-up training to engineering support and technical guidance, we help customers achieve accurate, reliable flow measurement at every stage. Our capabilities include meter rehabilitation, laboratory calibration, hydraulic analysis, and advanced CFD modeling, ensuring precision solutions tailored to your system’s needs.

Certifications

PFS maintains ASME S & U, European Pressure Equipment Directive (PED) and ISO 9001 certifications. All products can also be supplied with Canadian Registration Number (CRN).