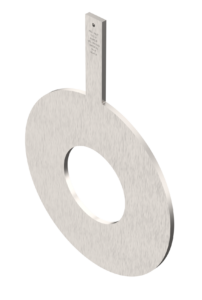

Orifice Plates (OP)

Flow Measurement / Flow Restriction

+/- 0.5-0.75% Uncalibrated Uncertainty

Liquids and Gases, Lower Cost

- Line size: 1/2 to 40 inches

- Meets ISO, AGA, ASME, API requirements

- Recommended pipe Reynolds number: Greater than 10,000 basic accuracy

Description

Orifice plates are common differential producer type flow elements for the measurement of liquids, gases and steam flow. Orifice plates are used for measuring and controlling fluid flow and can also be used to reduce pressure in a pipe system. The concentric, square edge type of orifice plate is the most frequently used, offering low cost, accuracy, ease of installation and rapid availability.

Specifications

Support and Service

In addition to a wide range of differential producing Venturi flow meters, orifice plates, WedgeType™ flow meters, and open channel flow elements, PFS provides comprehensive, specialized services for new and existing flow meters, including rehabilitation, hydraulic analysis, and full engineering support.

Certifications

ISO 9001, ASME S&U, PED Certified, CRN.