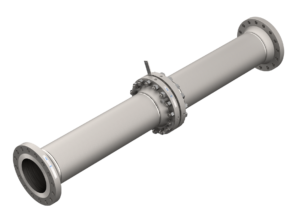

Orifice Meter Runs

+/- 0.5 to 0.75% Uncalibrated Uncertainty

Liquids and Gases, pipe spools included

- Honing available

- Meets ISO, AGA, ASME, API Requirements

- Supplied with any combination of NDE required

Description

Orifice Meter Runs are complete flow measurement devices, ready for installation, that include a manufacturer installed Orifice Union and Orifice Plate and the required up & down stream pipe sections. Stated uncertainties are contingent upon all code prescribed tolerances and finishes being met. The selection of a complete meter run ensures full conformance to all code specified geometric tolerances and finishes. In cases of smaller line sizes, the pipe sections may require honing in order to be compliant with the applicable code required finish. A fully fabricated run, complete with any variation of NDE required, is the only way to ensure this compliance.

Specifications

Support and Service

In addition to a wide range of differential producing Venturi flow meters, orifice plates, WedgeType™ flow meters, and open channel flow elements, PFS provides comprehensive, specialized services for new and existing flow meters, including rehabilitation, hydraulic analysis, and full engineering support.

Certifications

ISO 9001, ASME S&U, PED Certified, CRN.