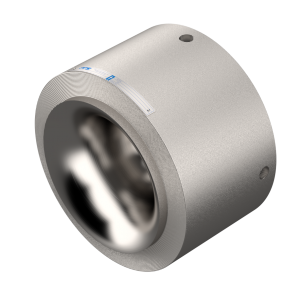

ASME PTC 19.5 Throat Tap Nozzle

+/- 0.70% Uncalibrated Uncertainty

High Accuracy

- Line size: 4 to 28 inches

- Head Loss (permanent pressure loss) in % of Differential: 60% to 85% (18% to 25% with optional outlet diffuser cone), Beta Dependent

- Recommended Application, THROAT Reynolds Number: Greater than 500,000 for basic accuracy

Description

The ASME Throat Tap Flow Nozzle provides high accuracy and precision which is used for the testing of steam turbine efficiency as prescribed in the ASME PTC-6 2004 Performance Test Code. The difference between a standard ASME Throat Tap nozzle and a PTC-6 Flow Nozzle is there is more flexibility in application and calibration with a standard ASME Throat Tap Nozzle. A standard Throat Tap Nozzle is recommended to be processed the same as a PTC-6 nozzle, but it is not required. IE, calibration is optional and up/down spools and other components are also optional.

Specifications

Support and Service

In addition to a wide range of differential producing Venturi flow meters, orifice plates, WedgeType™ flow meters, and open channel flow elements, PFS provides comprehensive, specialized services for new and existing flow meters, including rehabilitation, hydraulic analysis, and full engineering support.

Certifications

ISO 9001, ASME S&U, PED Certified, CRN.