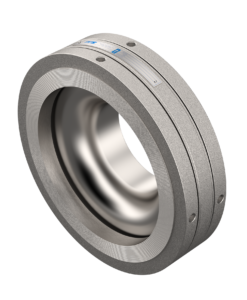

ISA 1932 Flow Nozzle

+/- 0.80% to 1.20% Uncalibrated Uncertainty

Liquids and Gases, Lower uncertainty

- Line size: 2 to 20 inches

- Head Loss % of Differential: 30 to 85, Beta Dependent

- Recommended Minimum Pipe Reynolds Number: Must be greater than 20,000 for basic accuracy

Description

The ISA 1932 flow nozzle is generally used for the measurement of liquid or gas flows including steam, erosive, high-velocity and non-viscous media. They do not rely on a sharp edge (which can deteriorate over time) to maintain accuracy and therefore offer excellent long-term accuracy with less wear, reducing the possibility of distortion. They are often used for high accuracy flow measurement in power plant applications.

The ISA 1932 flow nozzle is capable of measuring higher flow rates, often double, than an equivalent orifice plate at the same differential pressure. The flow nozzle is available in various designs including mechanically clamped between flanges or permanently welded directly into the pipe line.

Specifications

Support and Service

In addition to a wide range of differential producing Venturi flow meters, orifice plates, WedgeType™ flow meters, and open channel flow elements, PFS provides comprehensive, specialized services for new and existing flow meters, including rehabilitation, hydraulic analysis, and full engineering support.

Certifications

ISO 9001, ASME S&U, PED Certified, CRN.