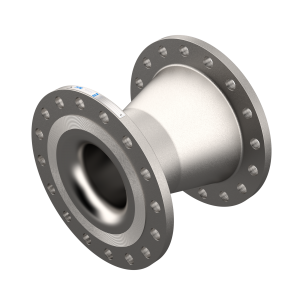

Venturi Nozzle

+/- 1.21% to 1.74% Uncalibrated Uncertainty

Liquids and Gases, Lower Loss

- Line size: 2.5 to 20 inches

- Head loss (permanent pressure loss) in % of Differential: 5% to 20%

- Recommended Pipe Reynolds Number: Greater than 150,000 for basic accuracy

Description

The Venturi Nozzle is a hybrid device having an inlet, convergent section identical to the ISA 1932 nozzle and an outlet, divergent section similar to a Venturi tube flowmeter. This results in a unique location for the low pressure tap in the throat. This design has a lower pressure loss than the ISA 1932 nozzle and the long radius nozzle.

They are generally used for the measurement of liquid or gas flows including steam, erosive, high-velocity and non-viscous media. They do not rely on a sharp edge (which can deteriorate over time) to maintain accuracy and therefore offer excellent long-term accuracy with less wear, reducing the possibility of distortion. They are often used for high accuracy flow measurement in power plant applications.

Specifications

Support and Service

In addition to a wide range of differential producing Venturi flow meters, orifice plates, WedgeType™ flow meters, and open channel flow elements, PFS provides comprehensive, specialized services for new and existing flow meters, including rehabilitation, hydraulic analysis, and full engineering support.

Certifications

ISO 9001, ASME S&U, PED Certified, CRN.