Industry-Leading Cast Iron & Ductile Iron Flow Control Products

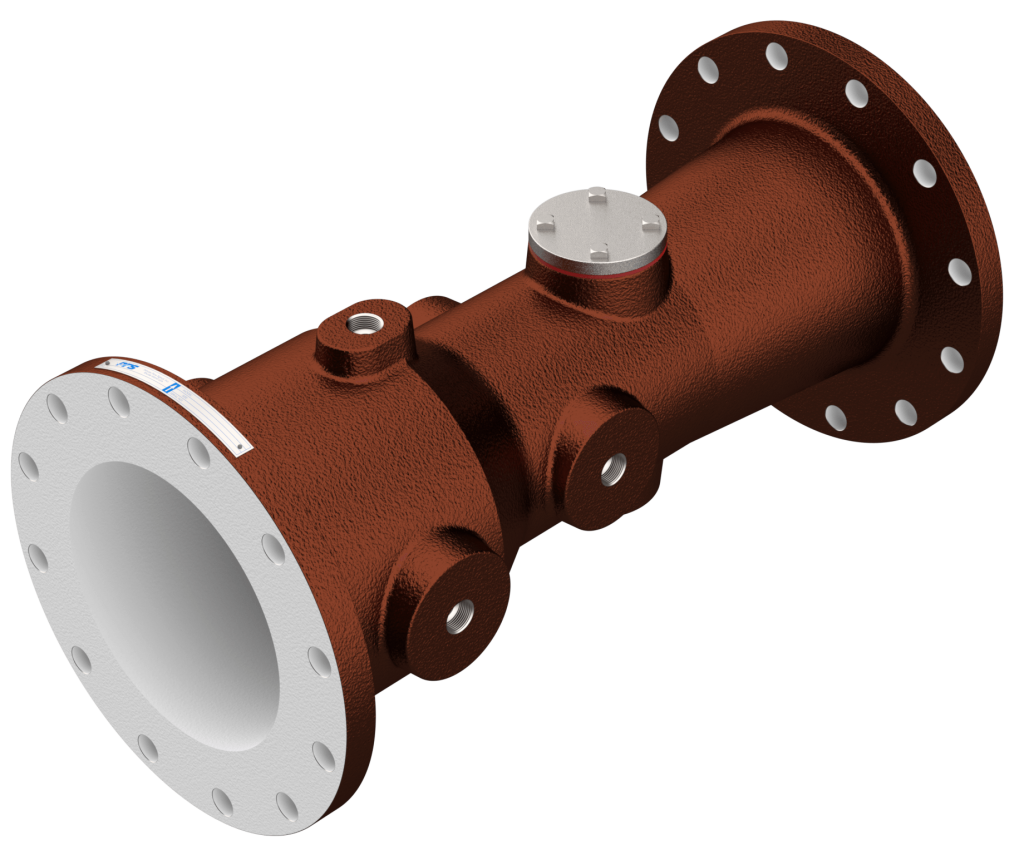

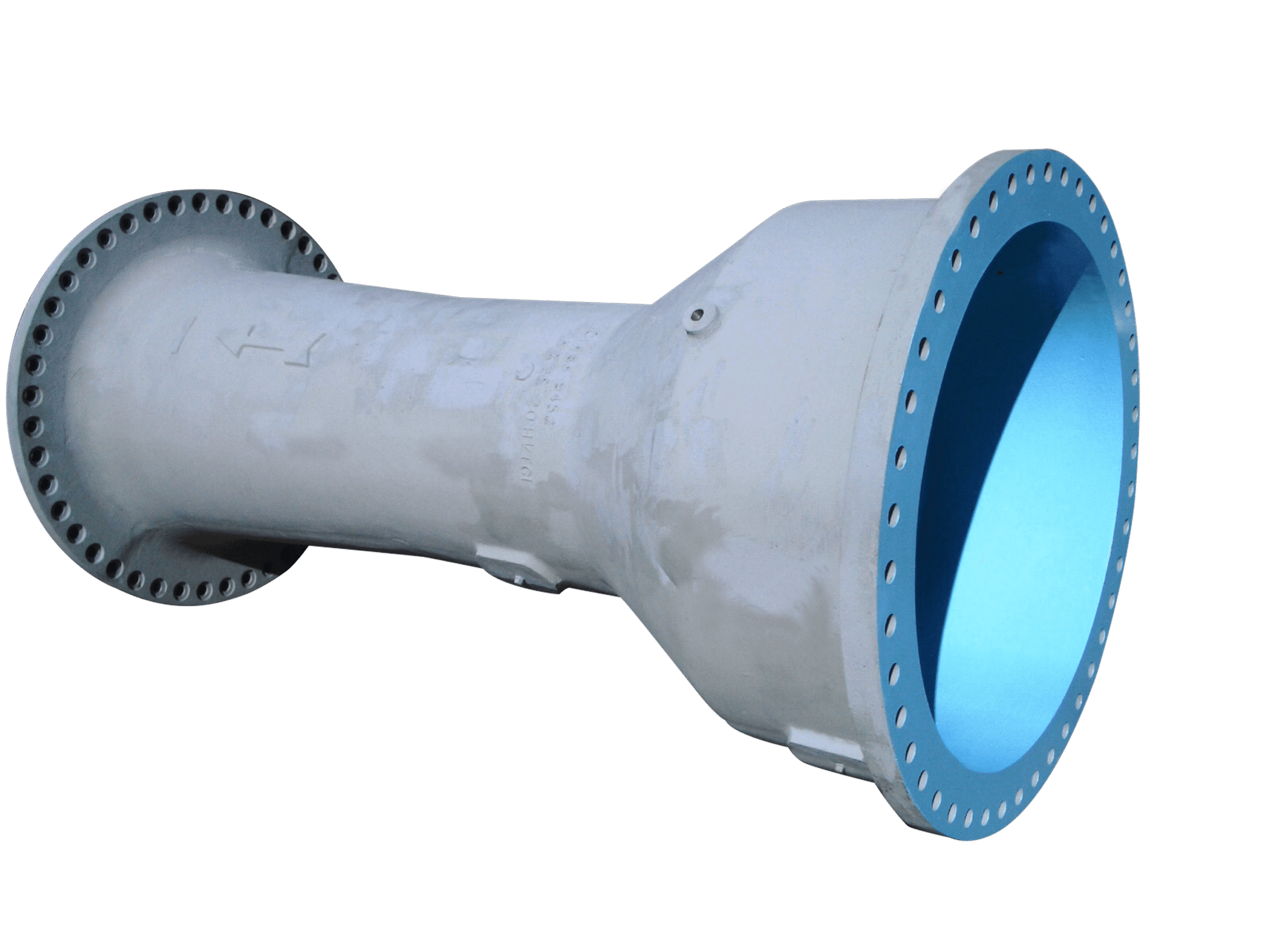

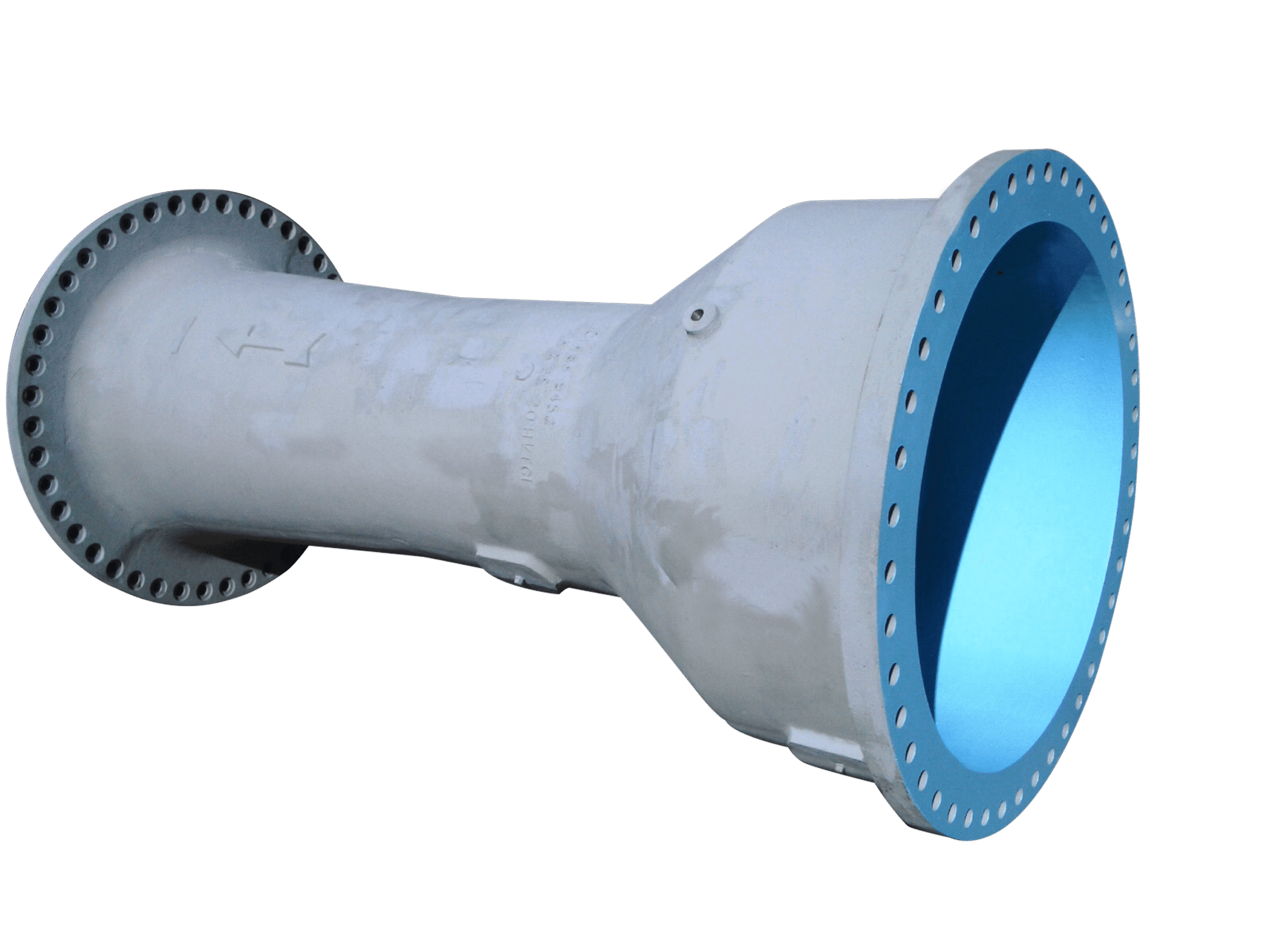

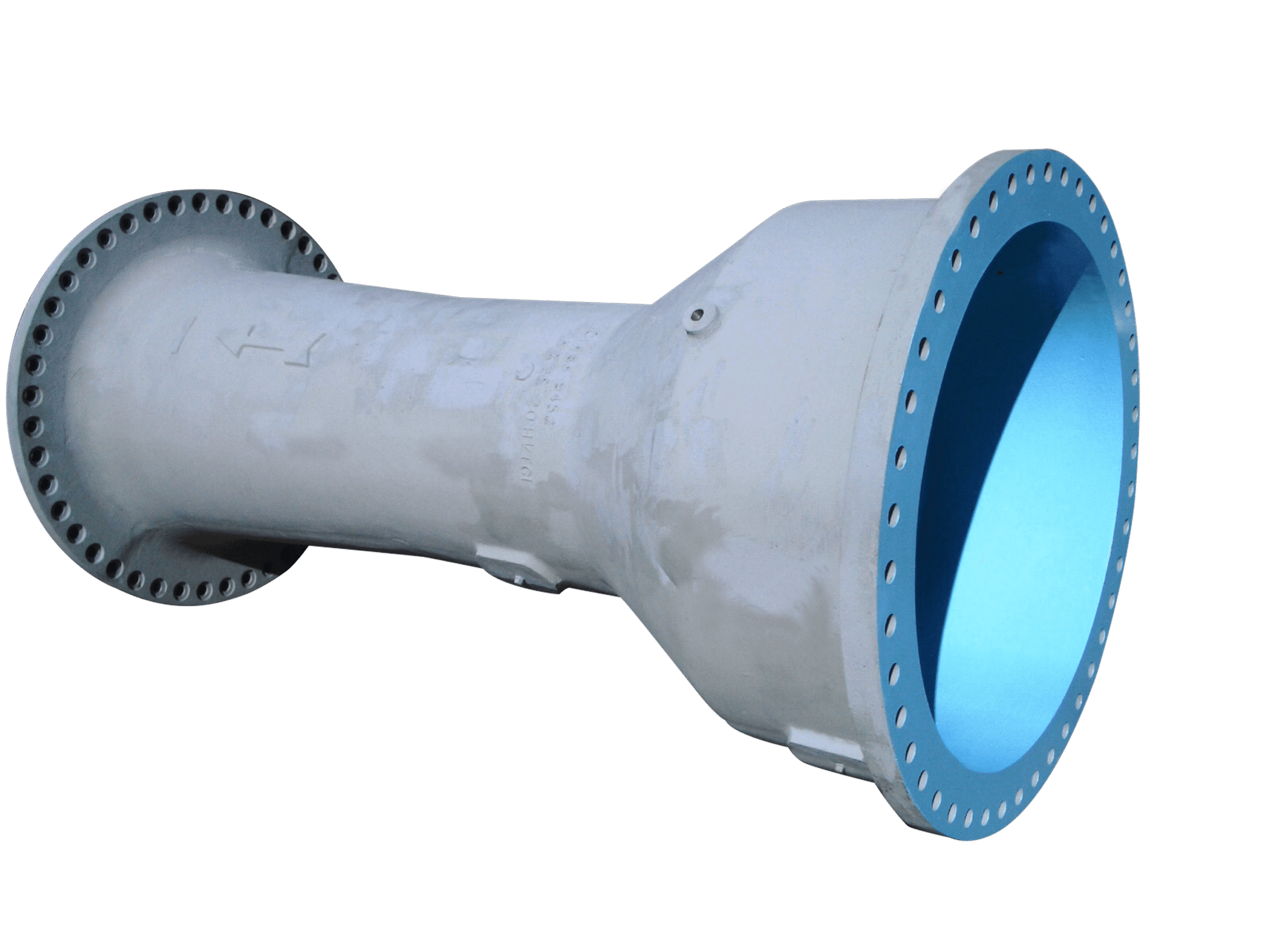

The HVT Venturi flow meter in cast iron (HVT-CI) and ductile iron (HVT-DI) is offered exclusively by Primary Flow Signal, Inc. to deliver the highest accuracy and reliability in flow measurement of pressurized line fluids. Proven across municipal and industrial applications, these meters are ideal for liquids, gases, solids-bearing flows, and harsh or contaminated line fluids.

The cast iron Venturi (HVT-CI) has an extensive track record in water and wastewater systems, while the ductile iron Venturi (HVT-DI) provides added strength for higher line pressure environments.

Outside of High Accuracy & Reliability, Key Benefits Include:

- Flow Control Integration: Optimized for use with close-coupled butterfly valves to create highly efficient rate-of-flow controllers for filter effluent applications.

- Solids-Bearing Capability: Configurable with remote diaphragm seals for accurate, reliable sewage flow measurement without the risk of plugged pressure taps.

- Proven Accuracy & Reliability: Repeatability of ±0.1%, wide turndown ratios (10:1, 20:1, 50:1+), and dependable performance in high-velocity applications.

- Durability & Longevity: Extended service life due to no moving parts, erosion-resistance and no annular chambers—eliminating plugging issues.

- Installation Flexibility: Compact design mounts in any orientation, with minimal upstream requirements and no downstream effect.

- Certified for Potable Water: NSF-61 approved coatings are standard for municipal and industrial water applications.

- Complete Turnkey Solutions: For fully integrated installations, the PFS Flow Master system pairs with any differential pressure device to provide complete control, management, and reporting functionality.

Specialized configurations are available to meet demanding applications, including integration with close-coupled butterfly valves to form highly efficient and effective flow rate controllers for filter effluent control, and remote diaphragm seals for reliable sewage flow measurement without blocked pressure taps. For turnkey installations, the PFS Flow Master system can also be paired with any dP device to deliver fully integrated control, management, and reporting capabilities.

Typical applications include raw water and wellfields, pumping stations, water treatment plant influent/effluent, filter effluent rate-of-flow control, water distribution and billing, reclaimed water, sewage collection systems, and potable or wastewater treatment processes, including installations requiring special lay lengths to fit existing piping constraints.

Cast Iron/Ductile Iron Venturi Flow Meter Specifications

Uncalibrated: +/- 0.50% (2 Sigma)

Cast Iron/Ductile Iron Flow Meter Model Types

Model Types

- HVT-CI – Cast Iron HVT Venturi

- HVT-DI – Ductile Iron HVT Venturi

- BCI – Bi-Directional Cast Iron HVT Venturi

- BDI – Bi-Directional Ductile Iron HVT Venturi

Cast Iron/Ductile Iron Meter Materials

Common Materials

- Cast iron or Ductile iron body

- 304 or 316SS throat

Cast Iron/Ductile Iron Venturi Meter Certifications

PFS is a contributor to various international standards committees, fully supporting our staff’s memberships to these commissions.

Individual products follow relevant industry regulations, including requirements specific to the oil and gas, water/wastewater, and power generation industries.

PFS maintains the following certifications, standards & compliances:

- ISO 9001

- AGA

- ASME S & U

- API

- ANSI

- European Pressure Equipment Directive (PED)

Applications

Municipal Water & Wastewater

Cast and ductile iron Venturi flow meters are commonly used for raw water, wellfields, and treatment plant influent/effluent measurement. Typical applications include pumping stations, reclaimed water systems, and billing or regulatory monitoring where NSF-61 coatings and long service life are required.

Sewage & Contaminated Flow

With remote diaphragm seals, these Venturi meters provide reliable measurement of sewage and contaminated fluids without plugged pressure taps—making them a low-maintenance solution for wastewater treatment and collection systems.

Industrial & Power Generation

Ductile iron Venturis are well suited for higher-pressure industrial applications, including process water, oil and gas, chemical processing, LNG, HRSG systems, and high-velocity steam or water service.

Filter Effluent & Flow Control

Paired with close-coupled butterfly valves, the HVT design delivers accurate filter effluent flow control, ideal for installations requiring precise regulation and compatibility with existing piping.

Cast Iron & Ductile Iron Flow Meter Expertise Since 1983

Proven Municipal & Industrial Performance

For more than 40 years, PFS has been the trusted leader in Venturi technology, with over one million installations worldwide. Unlike orifice plates, which can erode, clog, or require frequent replacement, our cast iron (HVT-CI) and ductile iron (HVT-DI) Venturi meters deliver dependable accuracy and long service life with no moving parts. The HVT-CI is widely used in municipal water and wastewater systems, while the HVT-DI provides added strength for higher-pressure applications.

Tailored Engineering & Long-Term Support

Every flow system is unique, and Venturi meters excel where durability and low pressure loss are critical. PFS engineers provide complete support, from hydraulic analysis, CFD modeling, and calibration to start-up assistance and flow control integration. Rehabilitation and recertification services extend meter life, making Venturis a lower total-cost solution compared to DP elements that require more frequent replacement or service.

Certifications & Compliance

Our cast and ductile iron Venturi meters are manufactured under the highest quality programs and international codes. PFS maintains ASME S & U, ISO 9001, and PED certifications, and products can be supplied with Canadian Registration Numbers (CRN) when required. NSF-61 approved coatings are also standard, ensuring safety in potable water applications.