WM Wedgetype Flow Meter

+/- 4.00% Uncalibrated Uncertainty

Dirty liquids and Slurries

- Line size: 1/2 to 30 inches

- Head loss % of Differential: 25 to 60 percent

- Recommended pipe Reynolds number: Must be greater than 500 for basic accuracy

Description

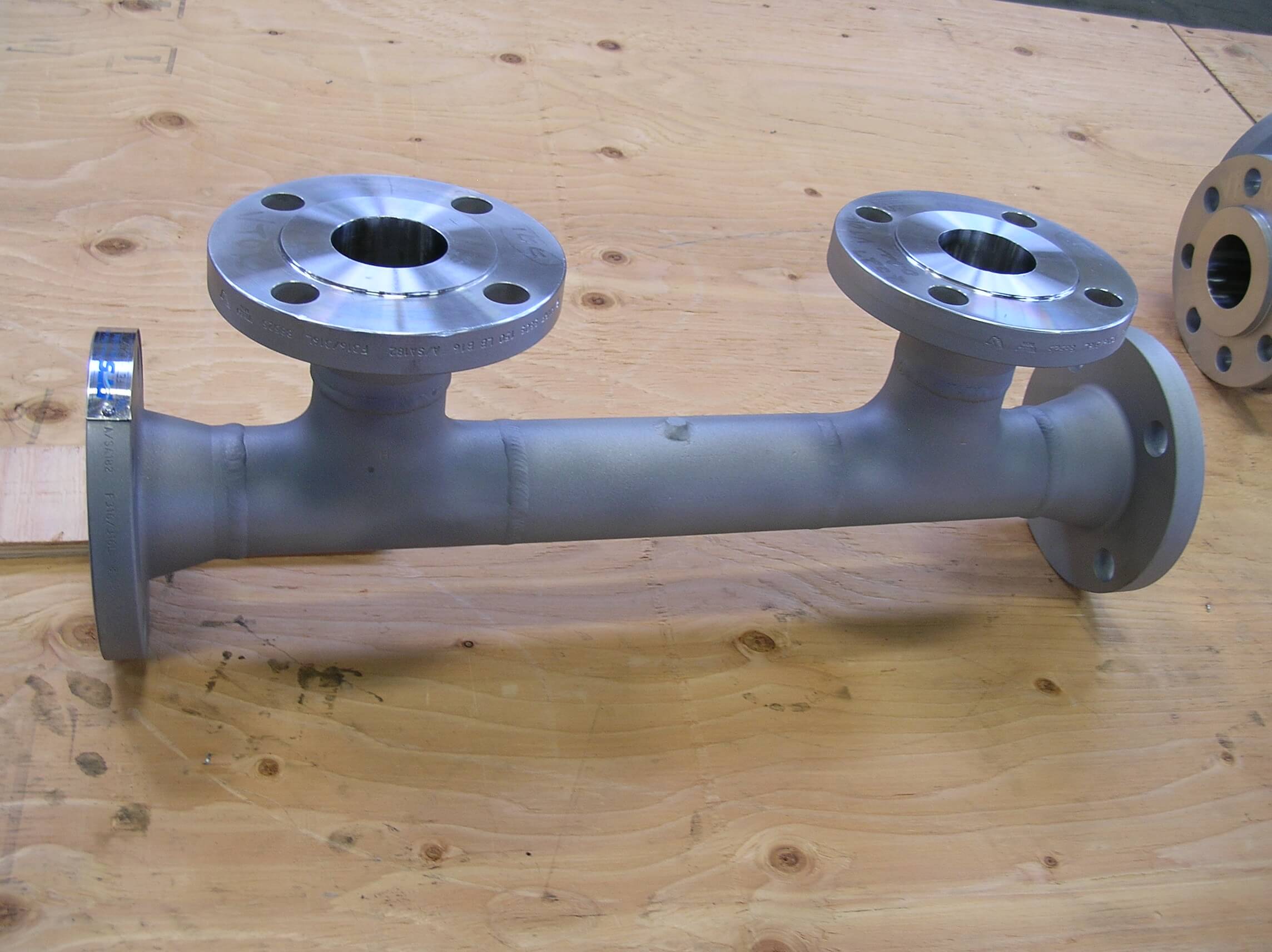

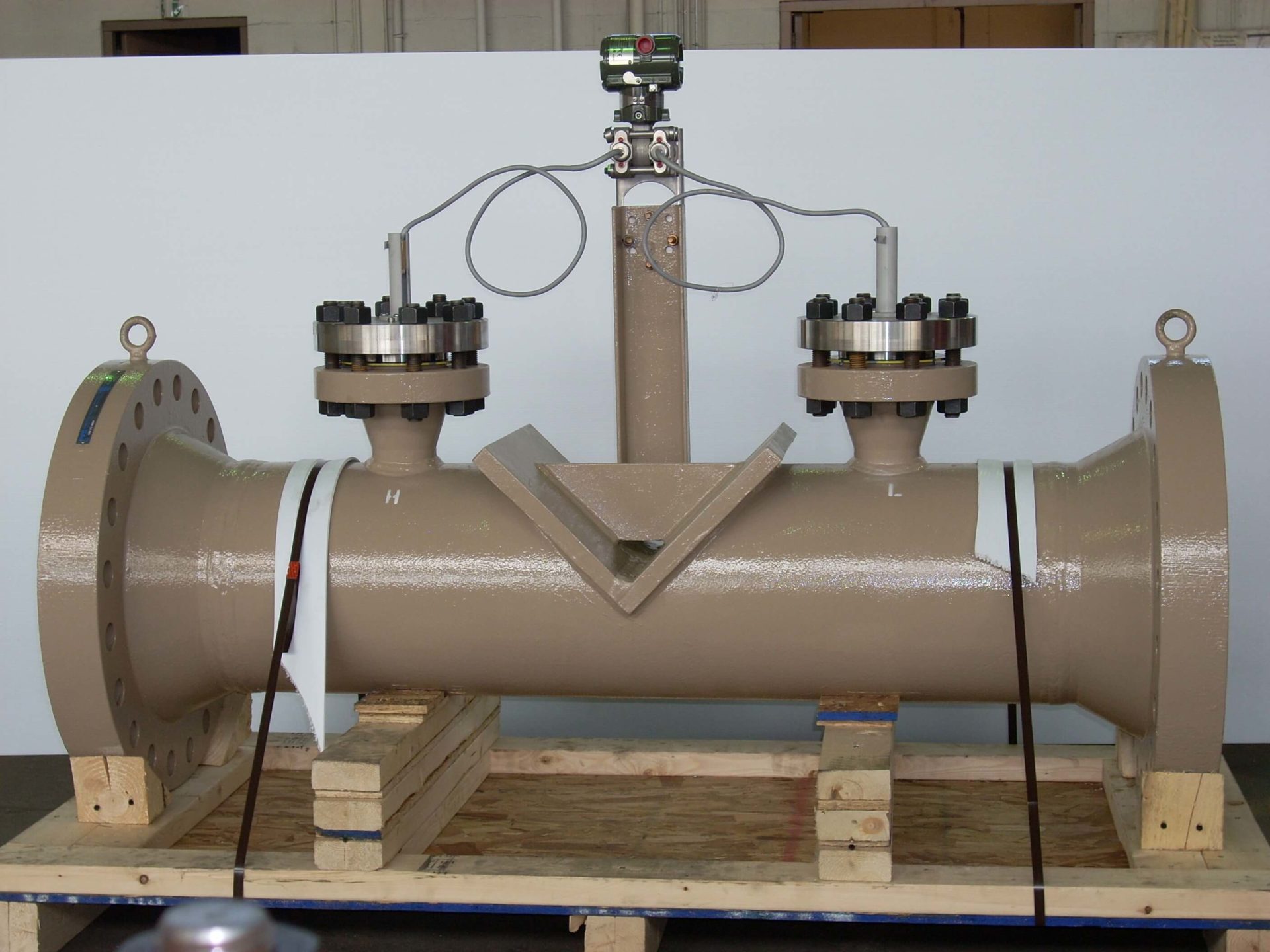

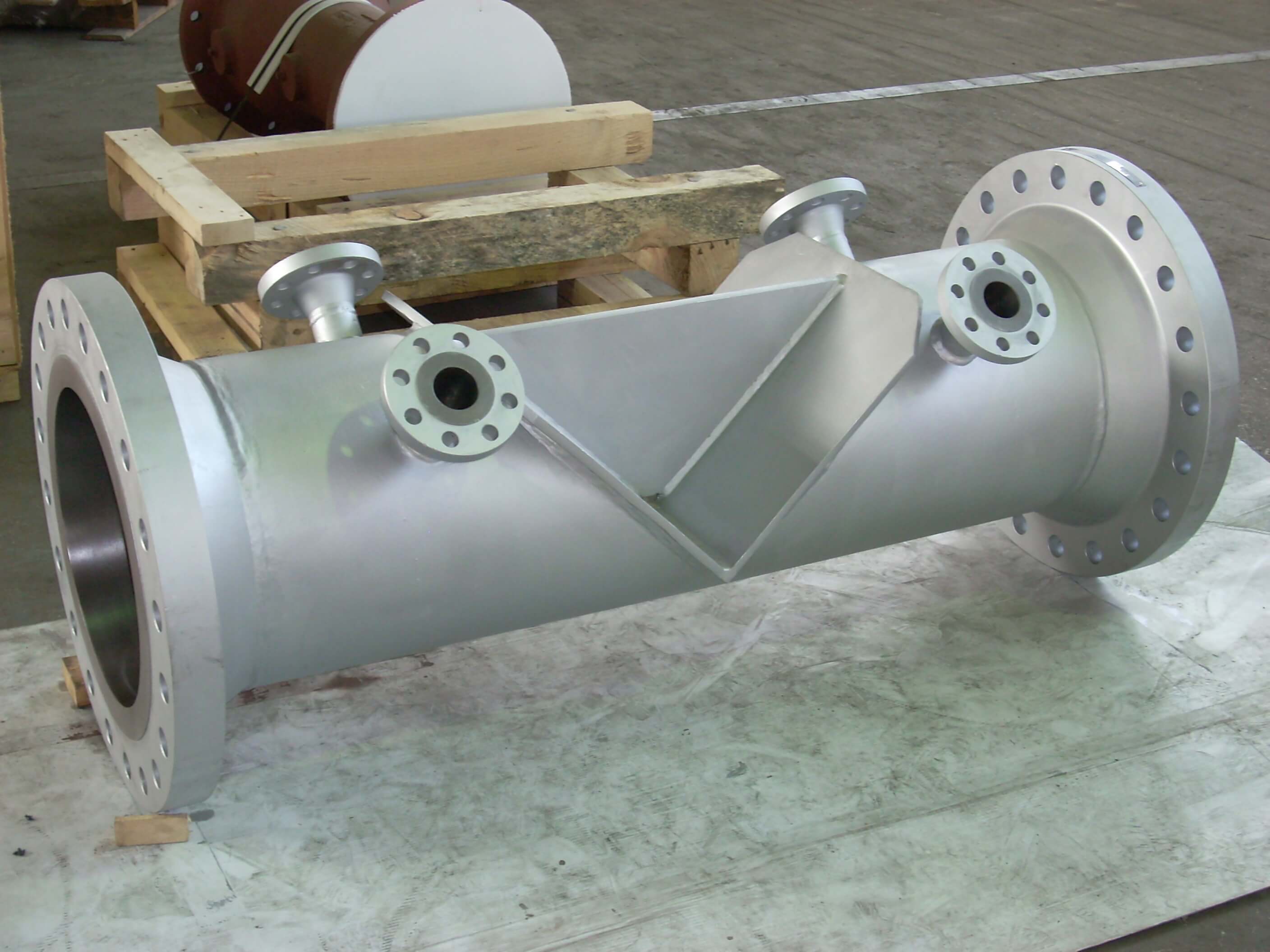

The WM wedge flow meter consists of a pipe inside which a V-shaped wedge is fitted. The basic system consists of a piping configuration into which a constriction “wedge” is fabricated thereby leaving an open segment of a known height. They are used for various process applications and conditions, especially slurries, suspended solids or viscous liquids. They can also be used for clean liquids, gas, air and steam.

Low pipe Reynolds flow applications can be measured with relative accuracy and the discharge coefficient is stable through the application range. The differential pressure is measured by a differential pressure transmitter.

Specifications

| Line Size | Wet Calibrated | Uncalibrated |

|---|---|---|

| 1/2" | +/- 0.75 | +/- 5.00 |

| 1-30" | +/- 0.50 | +/- 3.00 |

Support and Service

In addition to a wide range of differential producing Venturi flow meters, orifice plates, WedgeType™ flow meters, and open channel flow elements, PFS provides comprehensive, specialized services for new and existing flow meters, including rehabilitation, hydraulic analysis, and full engineering support.

Certifications

ISO 9001, ASME S&U, PED Certified, CRN.