Compact & Cost-Effective Wedge-X Flow Meters

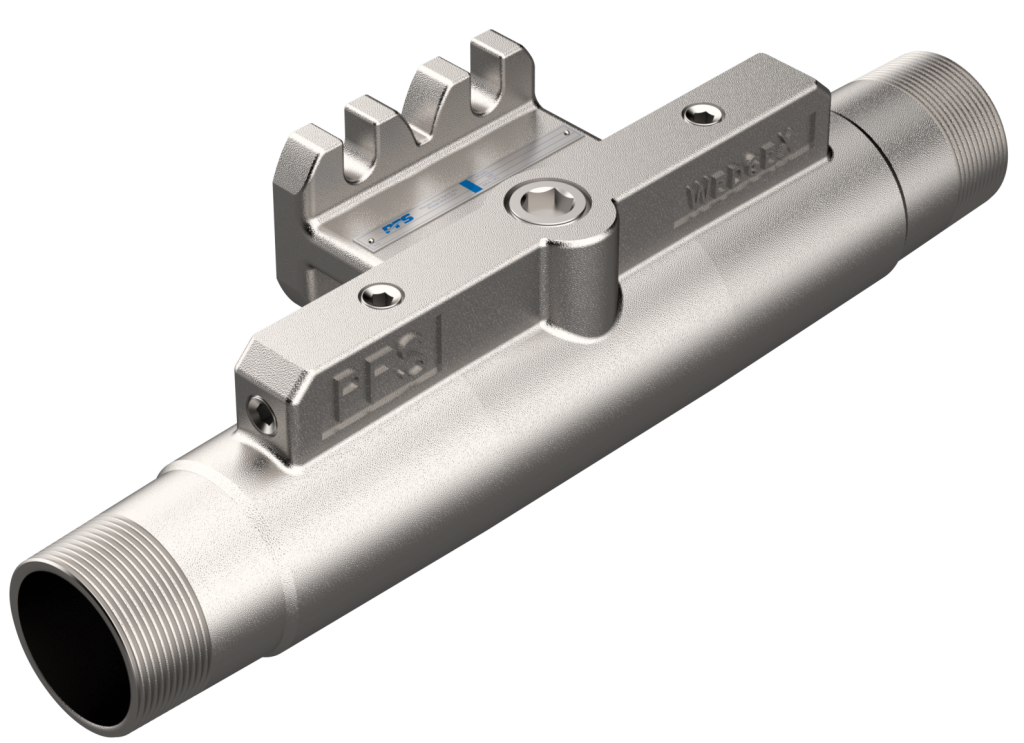

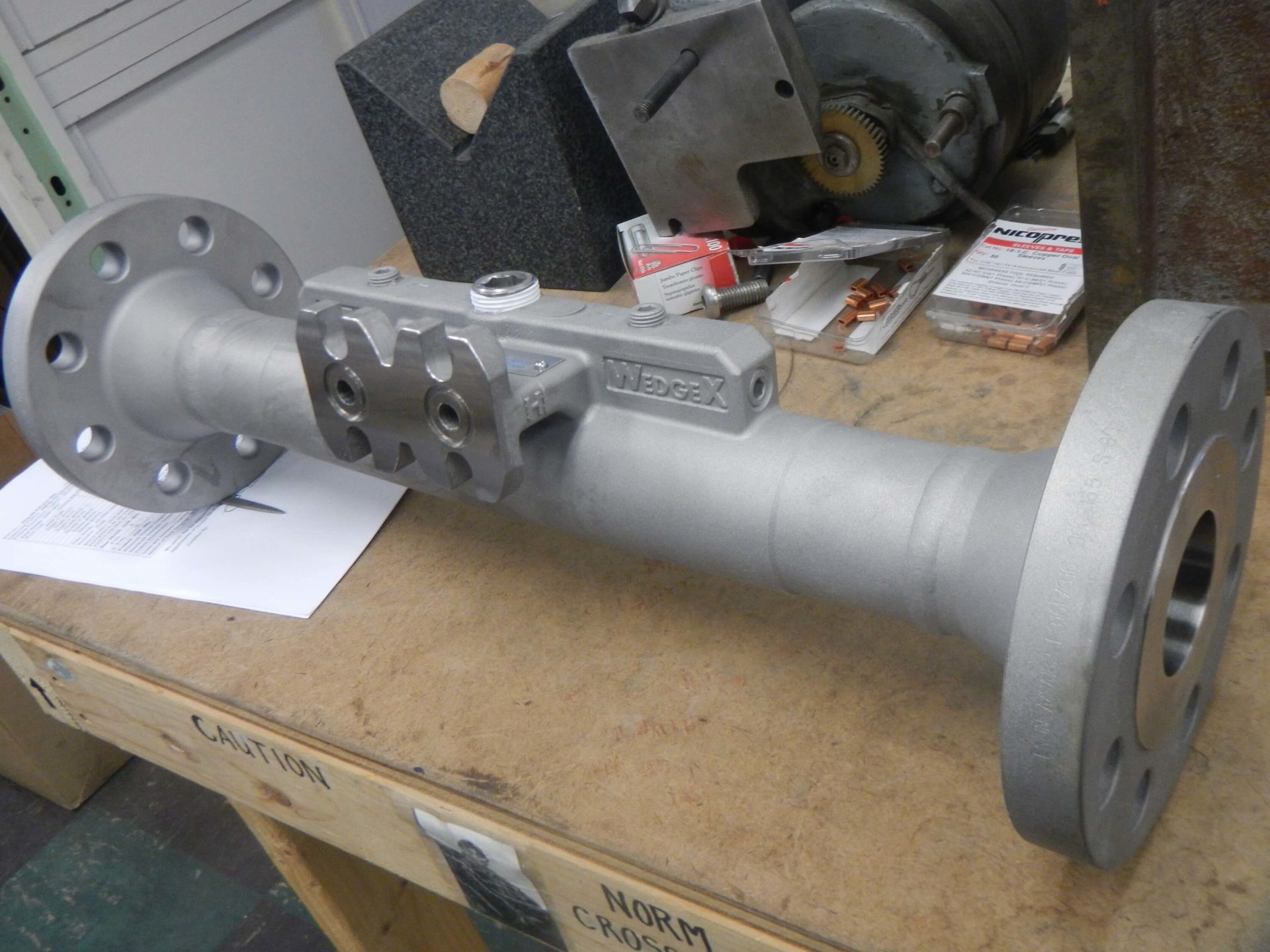

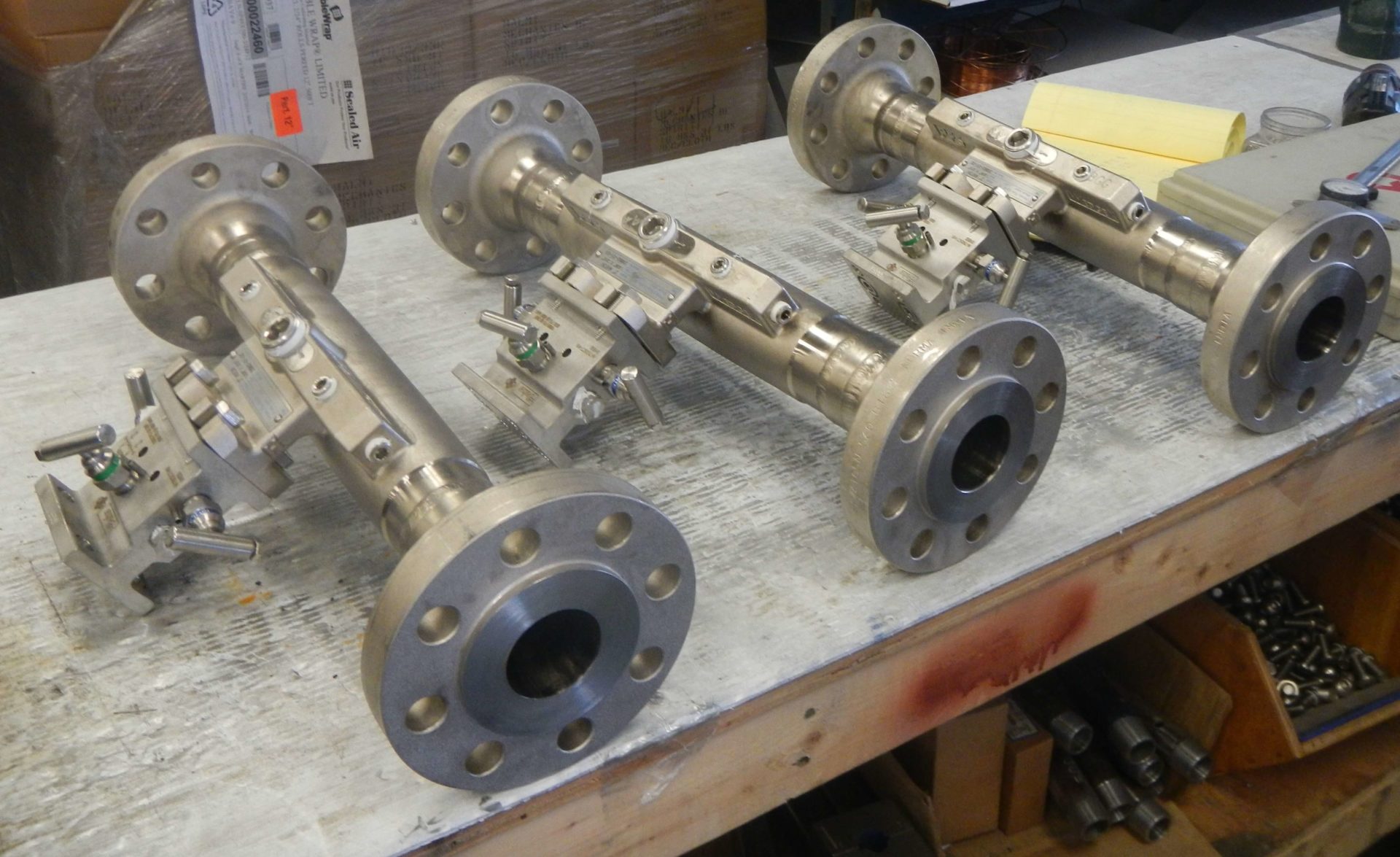

The Wedge-X Flow Meter from Primary Flow Signal builds on the proven performance of standard wedge meters, with a streamlined design that allows for a directly coupled differential pressure transmitter and a replaceable wedge element. This compact, all-in-one configuration reduces installation complexity, eliminates gauge line–induced and plugged tap errors, and provides a cost-effective solution for accurate flow measurement in challenging applications.

Wedge-X meters are engineered for high-density, slurry-type, or contaminated line fluids, including air-entrained liquids that are difficult to measure with other devices. With the ability to customize for a wide range of pressures and Reynolds numbers, the Wedge-X is well-suited for industries such as oil and gas (including shale gas extraction), mining, chemical processing, and other heavy-duty applications. The replaceable wedge feature further extends product life by allowing for quick and inexpensive replacement due to erosion, or by swapping in a different size wedge to adjust differential pressure as needed. Additional benefits of the Wedge-X meter include:

- Compact, Integrated Design: Combines the wedge element, meter body, and differential pressure transmitter into a single assembly—simplifying installation and reducing potential leak points.

- Replaceable Wedge Element: Provides a fast and economical way to address wedge wear or to change wedge sizing for different flow conditions without replacing the entire meter.

- Reliable in Harsh Applications: Performs consistently with slurries, viscous fluids, suspended solids, and contaminated or air-entrained liquids where other meters may fail.

- Extended Service Life & Durability: No moving parts and reduced susceptibility to erosion ensure long-term, low-maintenance performance.

- Versatile Operation: Bi-directional measurement, wide turndown ratio, and repeatability of ±0.2% make the Wedge-X adaptable to a wide range of process conditions.

- Flexible Installation: Mounts in any position, with robust construction that supports demanding industrial environments.

Typical applications include chemical and petrochemical processing of corrosive or abrasive liquids, pulp and paper operations involving fibrous slurries and stock flows, mining and mineral processing with abrasive slurries, and oil, gas, and refinery applications including crude oil, multiphase streams, and contaminated process fluids. Wedge-X meters are also well-suited for high-viscosity, solids-bearing, or entrained-gas liquids, including specialized applications such as shale gas extraction, where stable, repeatable measurement is critical under demanding conditions.

Wedge-X Flow Meter Specifications

Uncalibrated: +/- 3.00

Consult PFS for required US & DS piping based on your specific application”

Wedge-X Flow Meter Model Types

Model Types

- WXT – Wedge, X, Threaded Ends

- WXF – Wedge, X Flanged Ends

- WXW – Wedge, X, Wafer Ends

- WXV – Wedge, X, Victaulic Ends

Wedge-X Flow Meter Materials

Common Materials

- Carbon Steel

- Stainless Steel / 316SS

Wedge-X Flow Meter Certifications

PFS is a contributor to various international standards committees, fully supporting our staff’s memberships to these commissions.

Individual products follow relevant industry regulations, including requirements specific to the oil and gas, water/wastewater, and power generation industries.

PFS maintains the following certifications, standards & compliances:

- ISO 9001

- AGA

- ASME S & U

- API

- ANSI

- European Pressure Equipment Directive (PED)

Applications

Industrial Process

Wedge-X meters are used in general industrial processes requiring reliable measurement of high-viscosity, solids-bearing, or entrained-gas liquids. Their compact, integrated design supports dependable performance in complex piping systems.

Chemical & Petrochemical

In chemical and petrochemical service, Wedge-X meters handle corrosive, abrasive, and viscous fluids. The rugged design and replaceable wedge element enable accurate measurement of slurries, multiphase flows, and challenging process streams.

Mining, Oil & Gas

Wedge-X meters perform reliably in abrasive mining slurries, crude oil, multiphase streams, and gas applications. Their tolerance for suspended solids and entrained gases makes them well suited for upstream, refining, and shale gas operations.

Pulp & Paper

In pulp and paper mills, Wedge-X meters accurately measure fibrous slurries and contaminated stock flows. The erosion-resistant design supports continuous-duty operation in demanding mill environments.

Wedge-X Flow Meter Expertise Since 1983

Proven Accuracy & Reliability in Harsh Applications

Built on more than 40 years of flow measurement expertise, the Wedge-X delivers dependable accuracy where other meters fail. Its compact, integrated design virtually eliminates gauge line errors and plugged taps, while the replaceable wedge element ensures consistent performance in abrasive, viscous, or solids-bearing fluids.

Tailored Engineering & Lifecycle Value

PFS engineers customize each Wedge-X for process conditions, from pressure ranges and Reynolds numbers to materials of construction. Support includes hydraulic analysis, CFD modeling, and laboratory calibration, as well as field services for start-up and long-term performance optimization. The replaceable wedge extends product life and lowers the total cost of ownership by reducing downtime and replacement expenses.

Certified Quality & Compliance

Every Wedge-X is manufactured to the highest standards, backed by ASME S & U, ISO 9001, and PED certifications. Units can also be supplied with Canadian Registration Numbers (CRN) when required. Robust quality programs and full traceability ensure compliance for critical applications across oil and gas, petrochemical, and industrial process industries.