Condensate Chambers Use and Applications

What are condensate chambers and where are they used?

Condensate chambers (also known as condensate seal pots) have been used for over 100 years to condense steam upstream of secondary instrumentation (typically a differential pressure transmitter). This protects the transmitter from excessive heat exposure. Typically, for steam applications, they are installed at the centerline (or slightly higher) of the DP transmitter which results in the condensate level in the high- and low-pressure impulse lines being maintained above the DP transmitter.

Condensate Chamber Applications

The principal application of condensate chambers is on steam service. They can also be used to isolate a DP transmitter from corrosive fluids on non-steam applications. The application requirements determine the number and location of the connections to the chamber.

Because of the potentially high line pressure and line temperature conditions for certain steam applications, condensate chambers that have few weld joints provide the most cost-effective solutions. While the typical condensate chamber has 3 or 4 tap connections (dependent on service requirements) the PFS solution includes custom connections to suit your specific application conditions.

Materials used for Condensate Chambers

There are a number of codes which define the design and materials for condensate applications, including ASME and PED. Materials can be carbon steel, various stainless-steel grades and other suitable alloys, or what is best determined to avoid corrosion, rusting or premature failure.

PFS Condensate Chambers Advantage

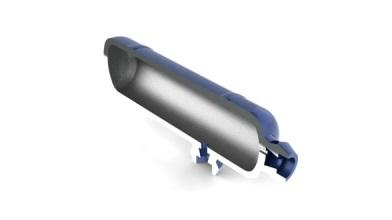

The PFS condensate chambers are designed and manufactured to meet temperature and pressure requirements based on customer specifications. While the most common material is stainless steel, a wide range of material options are available such as Chromoly Steels. Typical sizes are 3” and 4”, but other sizes and materials can be manufactured based on service requirements. Inlet, Outlet, Drain and Vent connections are attached based on service requirements. PFS offers a complete range of non-destructive testing (NDT) options in response to the need for long term performance with minimal maintenance.

Because the PFS chamber is built to order, a wide range of application requirements can be cost-effectively met without requiring a change to the application piping. PFS condensate chambers can be used on a wide variety of differential pressure type flowmeters such as the PFS-HVT-FV venturi meter, the PFS-CV Classical venturi meter and the PFS-OM orifice meter.

For additional guidance and discussion, please contact PFS!